#Data : An Important Piece To “The #InternetOfThings” Puzzle

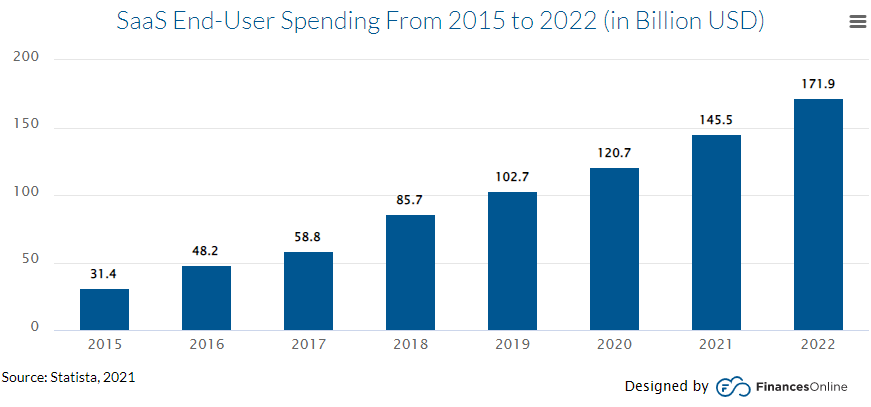

Every day, connected objects generate billions of information that must be processed and analyzed to make them usable. Thanks to the development of connectivity on multiple devices, the arrival of inexpensive sensors, and the data inflation they transmit, IoT have taken an irreplaceable place in our daily lives. IoT Analytics forecasts the IoT market size to grow at a CAGR of 22.0% to $525 billion from 2022 until 2027. The number of connected IoT devices growing 9% to 12.3 billion globally, and cellular IoT now surpassing 2 billion.

These very serious estimations do not, however, take into account the full extent of this digital revolution. If the design of connected objects is the showcase of the IoT and its vast possibilities, it still requires strong skills in the processing of the exploited data collected from sensors terminals, machines, and platforms to interpret it in order to boost productivity and increase performance.

Just as in the jewel market, the big winners are gold/diamond dealers. In the IoT domain, this role is played by companies able to manage the mountains of data generated by these connected devices because the collected data is profoundly changing the way businesses used to operate. Almost every day, new applications are imagined, with consequences at all levels of organizations because the real added value of connected objects only comes from the uses and the ability of companies to create new services.

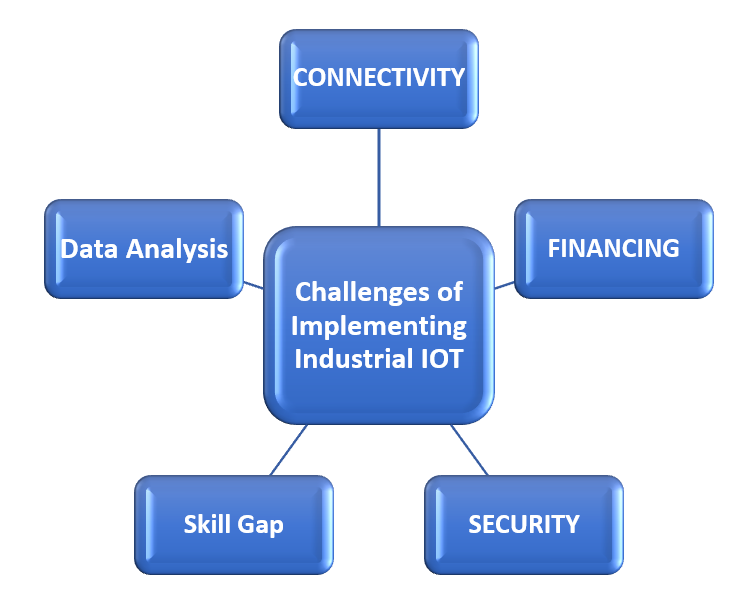

Several studies demonstrate that companies are still facing a gap between the collection of new data and the presentation of the analyzed information so that it can be understood and explored in great detail, whether it is for a connected house, connected car, or a portable terminal or an industrial solution.

Here below is the list of tips companies must consider before every IOT project implementation:

- Sort valuable information among a big volume of data:

Exploiting IoT means generating a huge amount of data. The challenge for companies is to filter the stray information and find the ones that are really important. This is why many companies integrate a flow analysis and a process analysis. The first provides real-time information from data streams such as navigation paths, logs, and measurement data, and the second is to take machine data captures.

- Set and manage priorities:

The IoT implies different levels of necessity in terms of urgency and latency. It’s important to take this into account because one expects to interact with the “real world” in real-time. For example, sensors in mines must trigger an alert as soon as they detect the presence of toxic gases. Similarly, other IoT information may not be needed “just in time”, such as regularly collected data to further refine and improve the predictive model itself. This data can potentially be collected and processed several times a day, for example.

- Design considerations for IoT technologies:

Information security, privacy, and data protection should systematically be worked at the design stage. Unfortunately, in many cases, they are added on later once the intended functionality is in place. This not only limits the effectiveness of the added-on information security and privacy measures but also is less efficient in terms of the cost to implement them. Although industries are actively working to address this, it stays a major IoT problem.

- Cross the Data:

In the case of preventive operations, for example, companies want to collect data from objects (such as smart meters) and cross them with relevant relational data, such as maintenance agreements, warranty information, and life cycle components. It is therefore essential that companies can rely on the data from which they make important decisions.

- Tracing the data:

The increased collection of data may raise issues of authentication and trust in the objects. In addition, it should also be noted that by using information collected about and from multiple objects related to a single person, that person may become more easily identifiable and better known. So in order to fully exploit the potential of IoT, tools must be much more flexible and allow users to shape and adapt data in different ways, depending on their needs or those of their organization.

Collaboration between the IT team and business experts is more critical than ever before in analyzing IoT data. In addition to those who understand the data, it takes experts to analyze gathered data from specific devices or sensors. While any analyst can understand the data in the context of a company’s performance indicators, only a data specialist would be able to explain what kind of hidden data contains a wealth of information, and how with the right tools, companies can unleash that potential.