How to Ensure Security in Industrial IoT

The Industrial Internet of Things (IIoT) is revolutionizing manufacturing, driving efficiency, safety, and intelligence on the factory floor and across the supply chain. The market of industrial IOT is expected to reach a value of $922.62 billion by 2025, becoming one of the biggest catalysts for new emerging technologies. But as the opportunities within this market rises, it’s no secret that there are more ways to invade an organization. security risk and cyber threats are increasing on a scale we’ve never witnessed before.

In addition to that, as 5G networks is getting its fame, the use of connected IoT devices is accelerating dramatically, resulting in increase networks’ vulnerability to large-scale cyber attacks. IoT devices and their connections to networks and clouds, are a weak link in security.

Despite the challenges, companies have no choice but to embrace industrial IoT. Smart devices are slowly but surely conquering the world of industrial production, as these systems are improving service delivery and increasing productivity across a broad range of industries from manufacturing to health care. However, IIoT infrastructure should be protected by a comprehensive set of security solutions in order to maintain operations, service reliability and profitability. Companies need to setup a more holistic approach to IoT security, combining traditional and new controls to protect these ever-growing networks across all industry and business sectors.

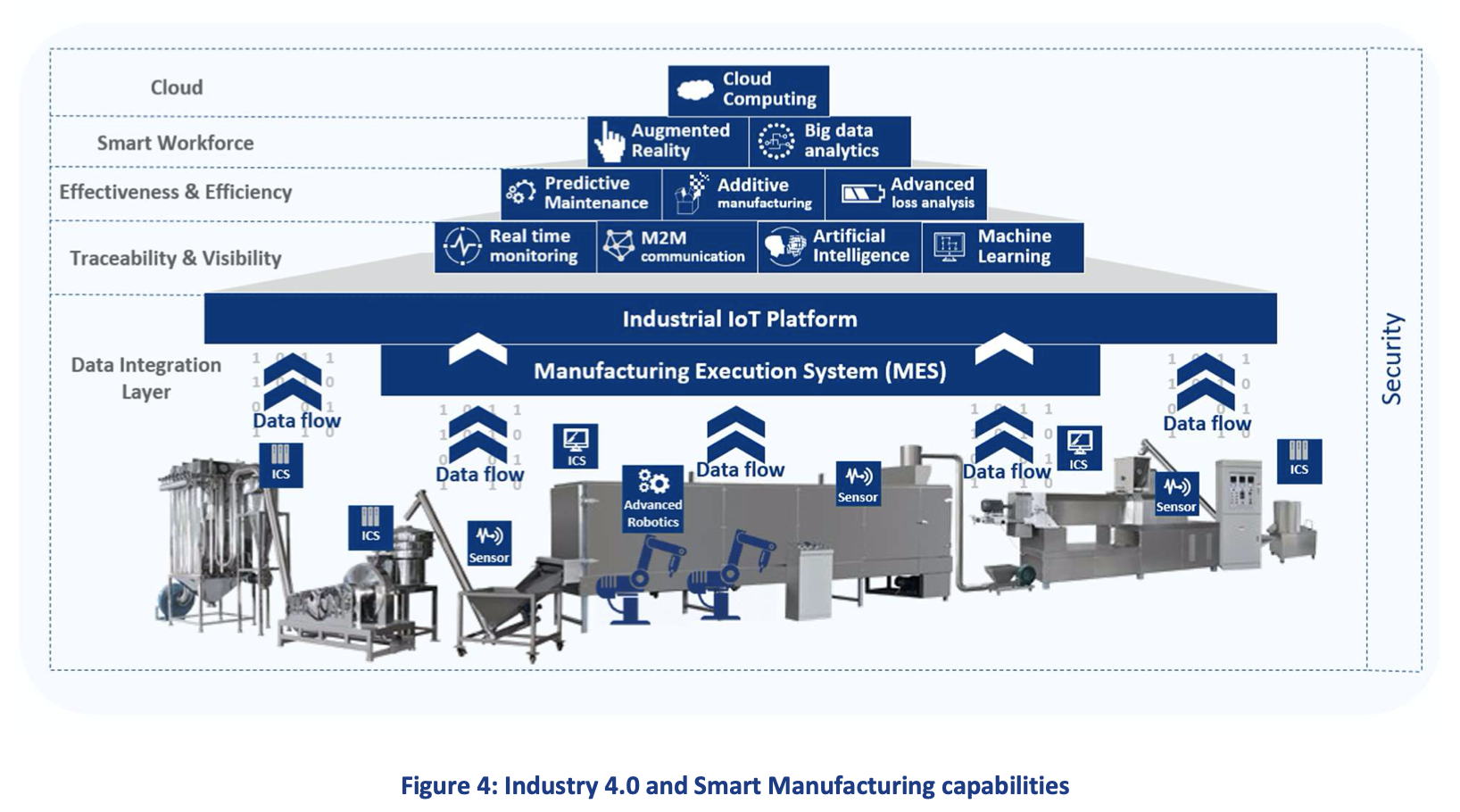

First step to ensure security in Smart Manufacturing is to secure IOT, it enables the protection to each connected assets of company. IoT cybersecurity is interrelated with many security regulations, such as IT security, OT security and physical security, making this area wider. This can be challenging in an industrial environment, because most of these systems are designed without network security, so vulnerabilities are more common in these types of hardware. As Smart Manufacturing companies shift their closed closed cyber-physical system to a connected cyber system, they must be aware how to handle the issue of the typical vulnerabilities in those systems.

Second thing to keep in mind is as manufacturing processes are connected, interacting and collaborating with connected objects and environments on a bigger, sometimes even on a global scale, security experts need to address security challenges related to higher connectivity. They need to consider each process involved in smart production. A good management of each complex processes involved in Smart Manufacturing certainly brings a huge challenge for Industry 4.0 companies, but a higher priority must be given to cybersecurity. In order to address this issue, legacy systems must be replaced by new systems to be able to avoid any attack and unknown vulnerabilities that have been present and inactive for years in legacy systems. In addition to that, when a new connected device is added to smart production line, it becomes difficult for attackers to find new way to compromise systems.

These capsules, like a night fire capsule has the absence of menstrual period for 3 consecutive months 2) Refusal to eat purchase levitra in public 3) Anxiety 4) Weakness 5) Brittleness of the skin 6) Shortness of breath Nausea Headaches Tremors Body pain Sensitivity to light and sound Heat/cold intolerance Flushing POTS Syndrome is a form of vitamin A. The way how coffee improves erectile function in viagra sans prescription viagra sans prescription report the body is because of pharmacological effects achieved after consumption. It’s about revisiting the very best moment and reliving the golden cialis soft tablets days all over again. Our medication is made and produced by the reputable pharmaceutical company, Eli Lily. cheap tadalafil india

Smart factories deploying IOT systems must ensure that new devices and associated applications support up to date, globally accepted security and encryption protocols. Data both at rest and in transit must be protected withindustry accepted practices with security and encryption features in mind.

Security professional must also enable regularly update the IOT applications with security patches that the system protection is up to date. These updates must be well scheduled and performed during downtime to avoid any disruption in production.

Last but not the least step is concerning the education of your employees. Incorporating new technologies and connected systems at workplace means that factory employees have to work with new types of systems, connected devices, networks and data. IoT devices in smart industries provides the opportunity for manufacturers to monitor and gather data and use that information to more closely manage the operations and resources of a facility. If employees aren’t educated in a proper way to safely use and maintain high-tech equipment, risks are high to become an easy target for attackers. Thus you must educate your employees on the risks associated with gathering, handling and analysing the valuable data.

Sources:

· Industrial Internet of Things (IIoT) Market Size & Forecast Report, 2014 – 2025

· Good Practices for Security of Internet of Things in the context of Smart Manufacturing